About Us

Our History

Hypneumat, Inc. began in the 1940s, when founder Earl Putrow developed the original concept and design for what would become the Hypneumat automatic drilling and tapping unit. The Hypneumat name was cleverly coined from three existing words: hydraulic, pneumatic, and automatic. Officially incorporated in 1950, Hypneumat Inc. quickly earned a reputation for manufacturing reliable, high-performance drilling and tapping equipment designed to serve a wide range of industrial applications.

With its early beginnings in northern Wisconsin, Hypneumat later established its long-term home in Franklin, Wisconsin, a suburb of Milwaukee, in the 1990s, where the company continues to operate today. As the business continued to grow, Hypneumat acquired the Commander and SNOW product lines in 2007 to better meet customer needs. Throughout its history, Hypneumat has remained a family-run business, maintaining a hands-on approach to both manufacturing and customer relationships.

What We Do

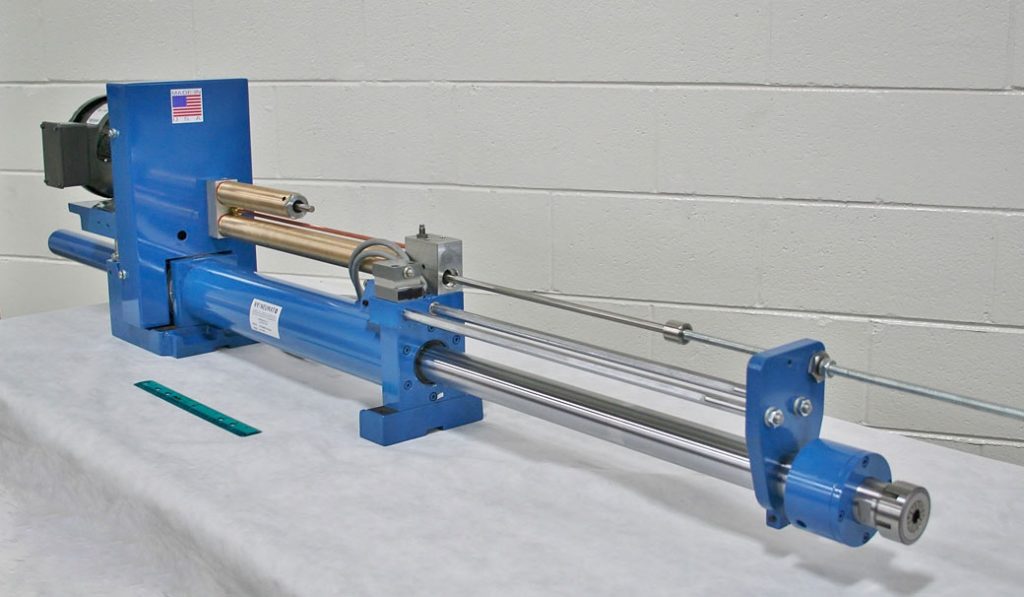

At Hypneumat, we specialize in manufacturing and supporting automated drilling units, tapping units, and multiple spindle heads that help businesses increase efficiency, consistency, and production throughput.

Our products include

- Autofeed Units (Automatic Drilling and Tapping Units)

- Multiple Spindle Heads

- Custom Automatic Drilling and Tapping Machines

- Replacement Parts for Hypneumat, Commander, and SNOW Line Products

Our services include

- Machining Services (Including Multi-Axis Turning And Vertical Machining Capabilities)

- Phone Support and Product Selection

- Repair Services and Troubleshooting

Our Experience

Our Experienced team has the knowledge and technical skill to provide dedicated phone, troubleshooting, and engineering support, ensuring you receive the timely assistance you need to reduce production downtime. We also offer dedicated repair services, allowing customers to ship their equipment to our location and our trained technicians will inspect, repair, and test, returning the product back to fully functional condition.

Because our equipment is customizable, we can continue to meet and exceed our customers’ developing needs. With over 80 years of continual operation in our industry, we have worked with various industries to meet their specific application needs, anywhere precision hole-making or tapping is required.

We partner with customers in industries including:

Automotive

Industrial

Aerospace

Woodworking

Food & Beverage

Construction & MORE

Why Work With Hypneumat

Hypneumat listens to the customer’s needs and delivers solutions to increase their production efficiency with reliability and longevity in mind. Our team designs and manufactures each unit according to our customers’ exact requirements, offering a larger variety of drilling, tapping, and multi-spindle heads.

We proudly maintain our ISO 9001:2015 certification, focusing on quality at every step of the manufacturing process to guarantee reliability and adherence to industry standards. We pride ourselves on our team of well-trained craftsmen and journeymen machinists who take personal pride in every build, from initial order to shipping.

Hyneumat is dedicated to investing in our local community and supports local Youth Apprenticeship programs in Wisconsin high schools, bridging the gap between classroom learning and real-world work experience for high school students. This program, offered statewide, allows students to gain valuable hands-on skills and knowledge in specific industries while earning high school credit.